日本這個國家在二次世界大戰之後百廢待舉 亟需出口貨品換取外匯

因緣際會之下戴明博士受邀到日本進行品質統計的教學 並且深受日本的推崇

時至今日 日本最高等級的品質獎項就叫做戴明獎 實在是對得獎者及戴明博士最高的肯定

戴明以統計學家的身份帶領日本及美國工業界找回產品的本質:品質

然而他本人卻看見了更多產業管理的缺失 並且指出這些缺失的來源來自於管理者本身

書名「轉危為安」就是戴明深刻感受到美國管理模式的傲慢所撰寫的一本書

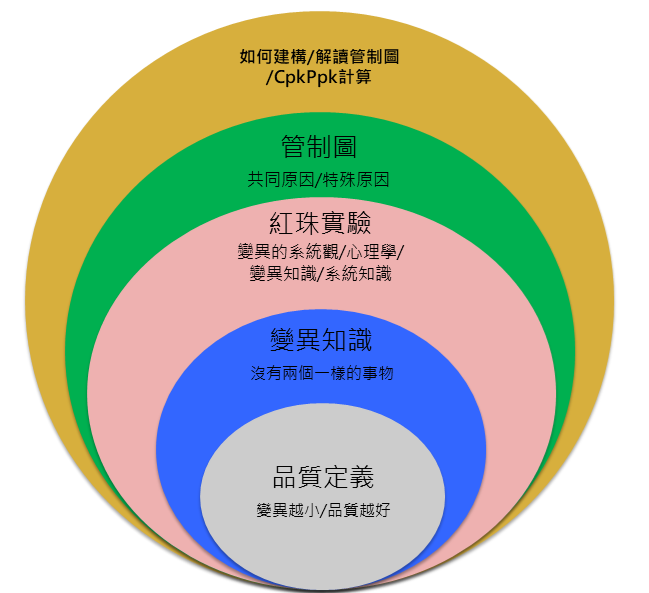

他積極提出了管理14項原則、紅珠實驗、漏斗實驗以及各式範例 舉證所有問題都源於管理

由此背景可知 他其實跳脫了各種品質工具的巢臼 認為品質不只是這些工具的應用

反而應該從「共同原因」著手 讓管理階層體認自己本身就是問題的起源

他在書中反覆提到美式管理的弊病 並且推崇日本的學習模式–品質是生產的首要目標

屏除數字管理 專注在品質改善 因而成功降低成本 增加顧客銷售

這些問題其實指向共通的毛病:

1. 依賴數字管理因而造成怠惰

2. 專注區域最低成本 因而忽略全域最佳成本的可能性

依成本數據管理供應商、依績效數據管理作業員、依進料合格率數據管理進料水準

這些業界慣用的手法一如往常造成諸多問題 卻被視為合理且不變的做法

不斷發生的進料異常、持續回饋的客訴問題 只是一再確認這些做法的嚴重性

戴明管理14項原則多有深意 但與許多目前台灣業界的做法大不相同

列舉此14項原則及其中文翻譯如下

我特別詳列14項原則的本文的用意是避免中文學習者能夠接觸原文

避免學習過程中因為翻譯的過程產生遺漏

從業品質管理一行七年多了 深感台灣企業高層對產品品質的不用心

因此當我回顧戴明博士的14項管理原則時 深感戚戚焉

也深自提醒自己有朝一日一日成為高階主管時 勢必反覆著墨這些原則

1. Create constancy of purpose toward improvement of product and service, with the aim to become competitive and to stay in business and to provide jobs.

打造持續改善產品及服務的環境

2. Adopt the new philosophy. We are in a new economic age. Western management must awaken to the challenge, must learn their responsibilities, and take on leadership for change.

接受新的管理哲學

3. Cease dependence on inspection to achieve quality. Eliminate the need for inspection on a mass basis by building quality into the product in the first place.

停止依賴檢驗!檢驗無法獲得品質

4. End the practice of awarding business on the basis of price tag. Instead, minimize total cost. Move toward a single supplier for any one item, on a long-term relationship of loyalty and trust.

採取降低總成本而非最低價格的做法 朝向單一供應商以維持長期的信任關係

5. Improve constantly and forever the system of production and service, to improve quality and productivity, and thus constantly decrease costs.

持續改善產品及服務、改善品質及生產效率進而持續降低成本

6. Institute training on the job.

建立在職訓練

7. Institute leadership. The aim of supervision should be to help people and machines and gadgets to do a better job. Supervision of management is in need of overhaul, as well as supervision of production workers.

建立領導方法

8. Drive out fear, so that everyone may work effectively for the company.

驅趕工作中的恐懼

9. Break down barriers between departments. People in research, design, sales and production must work as a team, to foresee problems of production and in use that may be encountered with the product or service.

降低部門間的溝通障礙

10. Eliminate slogans, exhortations, and targets for the work force asking for zero defects and new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the work force.

消除標語、規範、口號

11a. Eliminate work standards(quotas) on the factory floor. Substitute leadership.

以領導取代工作標準

11b. Eliminate management by objective. Eliminate management by numbers, numerical goals. Substitute leadership.

以領導取代目標管理、數字管理

12a. Remove barriers that rob the hourly worker of his right to pride of workmanship. The responsibility of supervisors must be changed from sheer numbers to quality.

讓作業人員以他們的工作為榮 領班應以品質作為第一目的

12b. Remove barriers that rob people in management and in engineering of their right to pride of workmanship. This means, inter alia, abolishment of the annual or merit rating and of management by objective.

讓管理階層及工程師以他們的工作為榮 去除績效評比及目標管理計畫

13. Institute a vigorous program of education and self-improvement.

建立訓練課程

14. Put everybody in the company to work to accomplish the transformation. The transformation is everybody’s job.

公司每個人都是轉變的主角